Neogi Pressure cum Vacuum Valve - Neogi PV VALVE 40mm & 50mm

Neogi PV VALVE Details

- • NEOGI PV VALVE 40MM/50MM APPROVED BY Petroleum & Safety Organization (PESO), Govt. of India & ATEX Germany

- • NEOGI PV VALVE 40MM/50MM USED FOR LIQUID SPECIALLY PETROLEUM PRODUCTS LIKE LDO, HSD, KEROSENE, FURNACE OIL, BIO DIESEL ETC. FUNCTIONS EQUALLY IN STATIC OR MOBILE CONDITIONS IN URBAN, SUBURBAN & RURAL AREAS.

- • We are instrumental in manufacturing, supplying and exporting premium quality NEOGI PV VALVE 40MM/50MM in India and abroad. The offered unit is manufactured under the supervision of our skilled professionals using the finest quality raw material and cutting edge technology in sync with set industry standards. Apart from this, provided unit is sternly tested by our quality controllers on variegated parameters so as to ensure its high performance.

- • NEOGI PV VALVE 40MM/50MM Minimize Evaporation loss & Maximize Profit

- • Neogi P V Valve (40mm/ 50mm) Pressure cum Vacuum Valve for your fuel storage tanks underground and or above ground

- • Pressure Vacuum (P V) valves, often referred to as breather valves or conservation valves, come into use when it was realized that evaporation losses could be substantially reduced by the application of P V valves instead of open vents

- Benefits

- • Neogi P V Valve protects volatile materials storage tanks against over / under pressure

- • Neogi P V Valve controls evaporation losses against open vents

- • Neogi P V Valve helps reduce the dispersion of gas in air and keeps environment clean

- • Neogi P V Valve is also a safe guard measure against fire compared to open vent system

- Function

- • Normally the closed parts in the valve are operated at a predetermined pressure or vacuum setting to allow the tank to ventilate to avoid explosion

- Unique Features

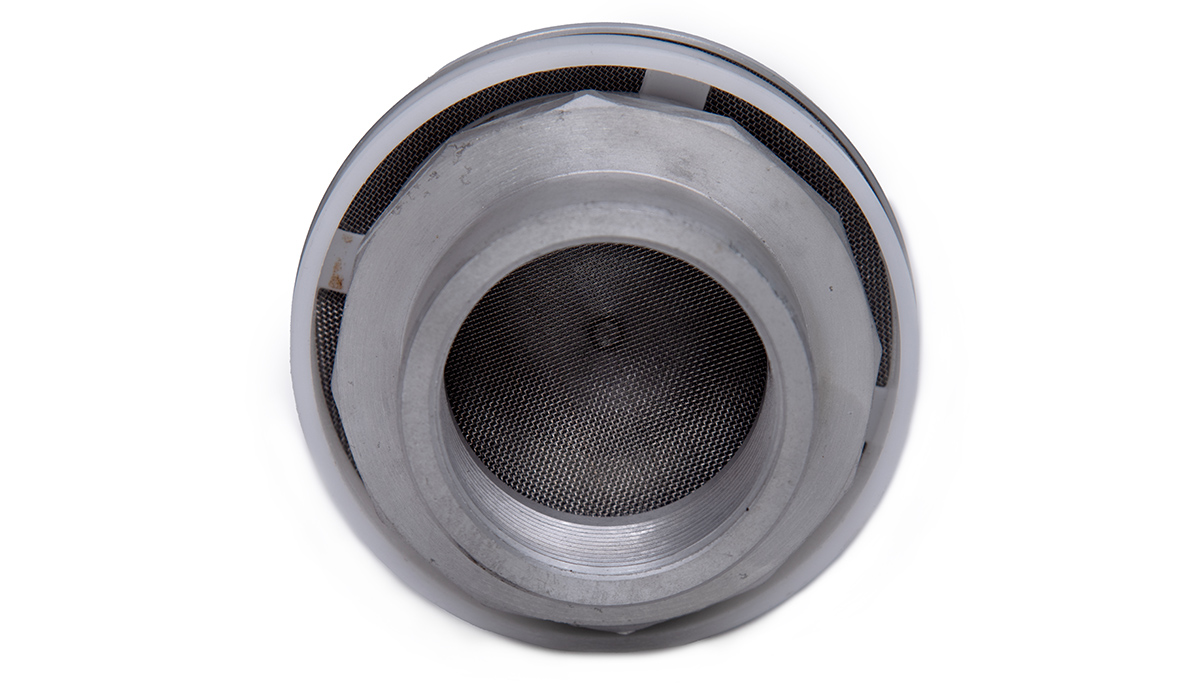

- • The main part of the valve is made of cast aluminium with SS wire mesh to protect it from foreign particles.

- The pressure / vacuum settings

- • For safe working, the pressure / vacuum setting at 3-inch (+/- 0.5 inch) water column pressure / vacuum setting at 8-inch (+/- 2 inch) water column vacuum are necessary. A built-in flame arrester with two layers of SS wire mesh. Neogi PV Valve prevents the intrusion of water, debris insects, duct etc.

- Installation

- • The Neogi P V Valve is installed on the top of the vent pipes of underground / above ground fuel storage tanks

- Maintenance

- • No special tools are required to carry out periodic maintenance. Periodically i.e at least once in a Six months SS/ Brass wire mesh should be cleaned for smooth functioning of the valve

NEOGI PV VALVE 40MM/50MM APPROVED BY Petroleum & Safety Organization (PESO), Govt. of India & ATEX Germany

PV VALVE Features

- NAME OF THE PRODUCT : Neogi PV Valve (Pressure cum Vacuum Valve)

- AVAILABLE MODELS : 2 INCH (50 mm) & 1.5 INCH (40 mm)

- MODEL NO: N/A

- APPROVAL MARK: N/A

- THREAD : BSP

- WEIGHT : 2INCH(50mm) – 664gm & 1.5INCH(40mm) – 656gm (APPROX)

- BODY MATERIAL : ALUMINIUM ALLOY

- FUNCTIONAL TEST AT : PRESSURE 3" (±0.5") OF WATER COLUMN & VACUUM 8" (±0.5") OF WATER COLUMN

- CERTIFICATION : ATEX Marking, PESO Govt. OF India

- INSTALATION : Can be installed on the tank having maximum 20 KL capacity

UNIQUE FEATURES :

- IT HAS A CONTINUOUS DUTY CYCLE

- The main part of the valve is made of cast aluminium with SS wire mesh to protect it from foreign particles.

- VERY EASY INSTALLATION & MAINTENANCE

- The pressure / vacuum settings For safe working, the pressure / vacuum setting at 3-inch (+/- 0.5 inch) water column pressure / pressure / vacuum setting at 8-inch (+/- 2 inch) water column vacuum settings are necessary. A built-in flame arrester with two layers of SS wire mesh. Neogi PV Valve prevents the intrusion of water, debris insects, duct etc.

- Installation: The Neogi P V Valve is installed on the top of the vent pipes of underground / above ground fuel storage tanks

- Maintenance : No special tools are required to carry out periodic maintenance. Periodically i.e at least once in a Six months SS/ Brass wire mesh should be cleaned for smooth functioning of the valve

- PROMPT AFTER SALE BACK UP SERVICE